Load capacity of suction cups - Euro-Tech (similar to 388 and 540 from Pannkoke): a study by the Kiel University of Applied Sciences (carried out in the second half of 2001) under the direction of Professor Dr Michael Klausner

Experimental setup

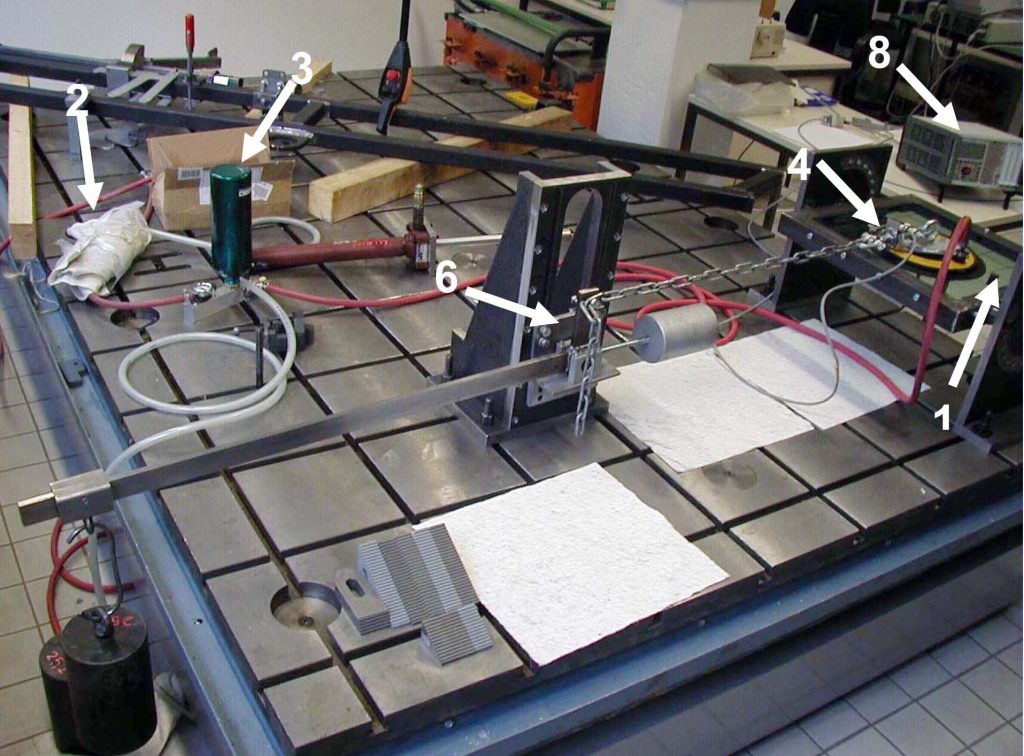

The suction cups are placed on a cleaned glass plate (1) as shown in Fig. 1 and connected to a vacuum of 0.6 bar; a Venturi nozzle with a noise-insulating jacket (2) and vacuum accumulator (3) serve as the vacuum supply.

A static force is exerted on the suction cup via the load cell (4) (type: HBM U2B 10 kN) by the weight-loaded lever (6), which is absorbed by the measuring bridge (8) (type: HBM MGC55-AB1).

Carrying out the experiment

The suction cups are pulled parallel to the glass plate, corresponding to the vertical lifting of glass panes.

In a first test run, the suction cups are quasi-statically loaded with a constant force and the tensile force and sliding movement are measured. The force is increased in stages if no sliding movement is observed within 5 minutes. The suction cups are picked up after each load increase and placed on the glass plate again and subjected to vacuum.

In a second test section, the suction cups are dynamically loaded until they break and the maximum force is recorded on the measuring bridge using the „peak hold display“.

Results

Suction cup Euro-Tech (similar to suction cup 388 from Pannkoke)

Static load:

The maximum static force is 1800N.

When the tensile force was increased further, the suction cup rubber detached from the aluminium base plate (failure pattern similar to Figure 3).

Dynamic load:

At a force of 4128 N, the suction cup rubber sticks to the glass plate and the metal ring that holds the rubber on the suction cup base plate deforms. The suction cup rubber then detaches from the base plate, the suction cup disintegrates and the rubber tears off the glass plate. The damage situation is documented in Fig. 3.

From this, it can be concluded that this suction cup has a high potential for failure in the event of force peaks due to the rubber-metal connection, which is not easily overloaded mechanically. Such force peaks can be caused by vibrations of the load or by lifting processes, especially with hydraulic cranes.

Suction cup Euro-Tech (similar to suction cup 540 from Pannkoke)

Static load

| Measuring time 5 minutes | |

| Force [N] | Distance [mm] |

| 780 | slips |

| 707 | slips |

| 637 | slips |

| 651 | 1 |

| 642 | 0 |

| 640 | 0 |

| 636 | 0 |

| 632 | 0,5 |

| 620 | 0 |

| 615 | 0 |

| 565 | 0 |

Dynamic load:

| Trial no. | Force [N] |

| 1 | 1368 |

| 2 | 1415 |

| 3 | 1374 |

| 4 | 1420 |

| 5 | 1390 |

| 6 | 1415 |

| 7 | 1419 |

| 8 | 1412 |

| 9 | 1410 |

| 10 | 1411 |

| Mean value [N] | 1403,4 |

Result:

Under static load, the suction cup can hold up to 641 N.

Under dynamic load, 1403 N are held.