Load capacity of suction cups 388 and 388-SI: an investigation by the Kiel University of Applied Sciences (carried out in the first half of 2004) under the direction of Professor Dr Michael Klausner

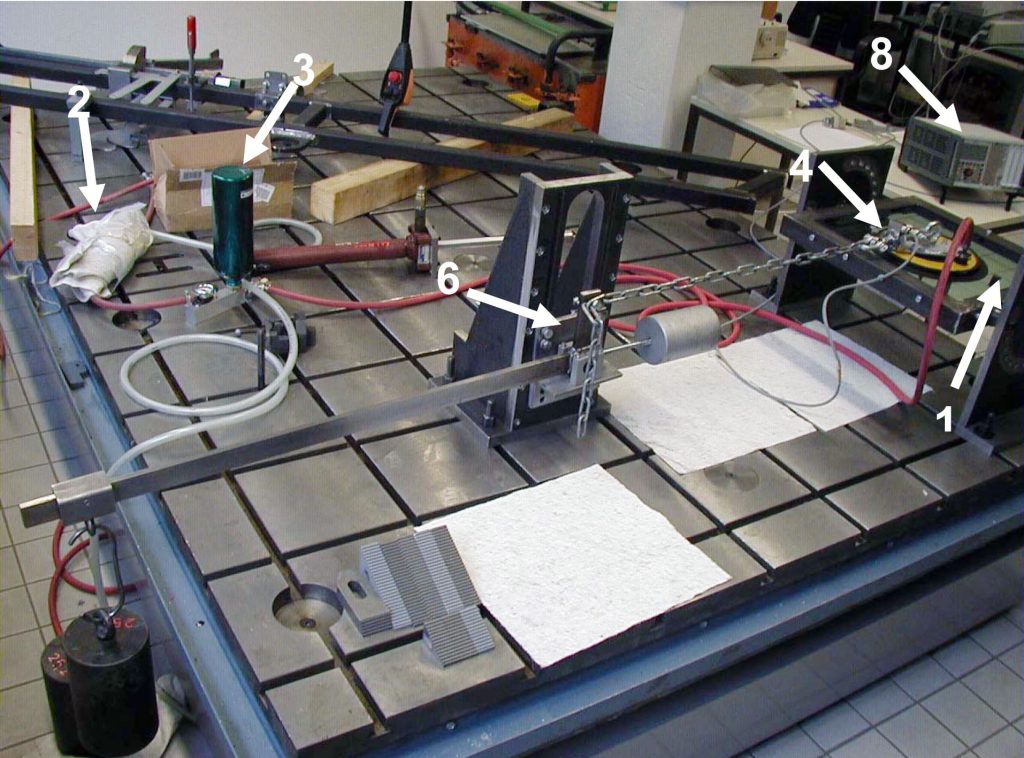

Experimental setup

At room temperature

The suction cups are placed on a cleaned glass plate (1) as shown in Fig. 1 and connected to a vacuum of 0.6 bar; a Venturi nozzle with a noise-insulating jacket (2) and vacuum accumulator (3) serve as the vacuum supply.

A static force is exerted on the suction cup via the load cell (4) (type: HBM U2B 10 kN) by the weight-loaded lever (6), which is absorbed by the measuring bridge (8) (type: HBM MGC55-AB1).

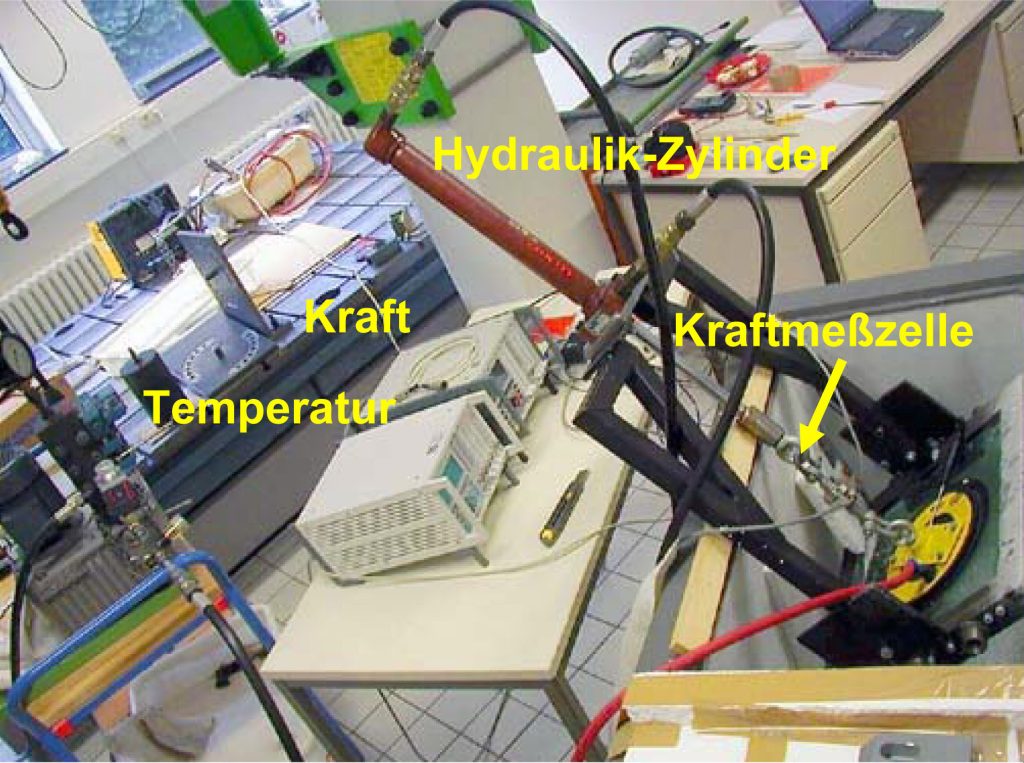

At low temperatures

The suction cups are placed on a cleaned glass plate and connected to a vacuum of 0.6 bar; a Venturi nozzle with vacuum accumulator serves as the vacuum supply. The entire test set-up is shown in Figure 2. The suction cups are dynamically loaded by a hydraulic cylinder, the tensile force is recorded by a load cell and registered by a measuring bridge. The peak value of the force is read off. For the tensile tests at right angles to the glass, the tensile device was positioned at an angle in the freezer; the resulting measurement error remains less than 0.3%.

When measuring the tensile direction parallel to the glass, the arrangement could be placed vertically. The tensile direction parallel to the glass is the load case when the glass is transported vertically.

Tests at room temperature

Suction cup 388 with labelling 080404 - 2

(new rubber compound used since May 2004)

The suction cup was statically loaded for slippage at room temperature.

Force Behaviour

2400 N Suction cup holds

2612 N Suction cup holds after approx. 2.5 mm creep phase of 3 min duration

2688 N Suction cup glides evenly at 4 mm / min

Suction cup 388 with labelling 080404 - 3

(new rubber compound used since May 2004)

The suction cup was statically loaded for slippage at room temperature.

Force Behaviour

2461 N Suction cup holds

2851 N Suction cup holds after 4 mm creep phase of 2 min duration

3123 N Suction cup holds after 9 mm creep phase of 7 min duration

3297 N Suction cup glides evenly at 8 mm / 2 min

Suction cup 388-SI with labelling 004/2004 C

(silicone, light grey, marked with felt-tip pen: 04/2004 „C“)

The suction cup was statically loaded for slippage at room temperature.

- Measurement series

Force Behaviour

1650 N Suction cup holds

1721 N Suction cup glides evenly at 2 mm/ 3 min

1751 N Suction cup glides evenly at 8 mm/ 3 min

- Measurement series

Force Behaviour

1708 N Suction cup holds

1789 N Suction cup holds after 5 mm creep phase of 3 min duration

1810 N Suction cup glides evenly at 10 mm / 3 min

Suction cup 388-SI with labelling 004/2004 D

(silicone, light grey, marked with felt-tip pen: 04/2004 „D“)

The suction cup was statically loaded for slippage at room temperature.

Force Behaviour

2120 N Suction cup holds

2286 N Suction cup slips immediately

Low temperature tests

- Measurement series, -20.2 °C

Suction cup 388 with labelling 080404 - 2 and 080404 - 3

(new rubber compound used since May 2004)

Suction cups are hard and cannot be made to suck in even by pressing on them.

Suction cup 388-SI with labelling 004/2004 C

(silicone, light grey, marked with felt-tip pen: 04/2004 „C“)

Force Behaviour

1487 N Suction cup holds

1972 N Suction cup glides evenly at 0.5 mm / 3 min

Suction cup 388-SI with labelling 004/2004 D

(silicone, light grey, marked with felt-tip pen: 04/2004 „D“)

Force Behaviour

1752 N Suction cup holds

2000 N Suction cup glides evenly at 0.5 mm / 7 min

2532 N Suction cup glides evenly at 0.5 mm / 2 min

2617 N Suction cup glides evenly at 0.5 mm / 0.5 min

- Measurement series, -33.6 °C

Suction cup 388 with labelling 080404 - 2 and 080404 - 3

(new rubber compound used since May 2004)

Suction cup hard, does not suck in even after pressing.

Suction cup 388-SI with labelling 004/2004 C

(silicone, light grey, marked with felt-tip pen: 04/2004 „C“)

Force Behaviour

1800 N Suction cup holds

2100 N Suction cup holds

2300 N Suction cup glides evenly at 0.5 mm / 10 min

Suction cup 388-SI with labelling 004/2004 D

(silicone, light grey, marked with felt-tip pen: 04/2004 „D“)

Force Behaviour

2500 N Suction cup slides less than 0.5 mm / 10 min, holds when reattached

3000 N Suction cup glides evenly at 1 mm / 6 min

3500 N Suction cup glides evenly at 1.5 mm / 1 min

Results

The suction cups made of the new rubber compound hold up to 2400 N at room temperature without slipping; above this, suction cup 080404 - 3 comes to a standstill at approx. 3000 N after a creep phase.

This value agrees well with the result of the first tests for the 388 suction cup with the new rubber compound (2300 N) from the report dated 4 May 2004.

At low temperatures, the new rubber quality is not usable at approx. -20°C.

The silicone suction cups are less resilient at room temperature, specimen „C“ held up to 1700 N, whereas „D“ could be loaded up to 2100 N. It was noticeable that the outer lip retracted strongly under the disc. This is probably due to the low hardness, but otherwise has no influence.

The silicone suction cups do not show any noticeable hardening up to approx. -20°C, so the slip resistance is similar to that at room temperature. At approx. -30°C, the suction cups become somewhat firmer and the forces that can be applied increase noticeably.

Overall, the good behaviour of the new rubber compound is confirmed. The silicone types are suitable for low temperatures.

Kiel, 8 June 2004

Prof. Dr.-Ing. Michael Klausner