The load capacity of a vacuum lifting device is not determined solely by the load capacity of the suction cups, but also depends to some extent on the size of the support frame

The maximum protrusion of the material to be lifted is very difficult to define and depends on many factors. The rigidity of the material is a very important factor. In general, the horizontal application is always the more critical case in this question. If the material protrudes too far and does not have sufficient stability, it will buckle.

Experiment:

Take a sheet of paper measuring 20 x 30 cm and place it in the centre over a pencil held up horizontally. How does your paper behave? Does it stay straight or does it hang down?

A sheet of paper placed over a pencil.

Now take two pencils, hold them approx. 1 cm apart and place the sheet of paper in the centre of both pencils. How does your paper behave?

You can continue this experiment by pulling the pencils further and further apart.

A sheet of paper placed over two pencils held further apart.

The result will be something like this: the further you pull the pins apart, the less bending of the blade ends you will achieve, up to the point that you get a deflection in the centre and need support there.

A sheet of paper placed over two pencils held at the ends of the sheet.

This experiment is a good illustration of horizontal transport. Can you now imagine how much strain is placed on the outer suction cups by the bending? And it is not only the bending, but also the forces caused by the corresponding lever arm that make it impossible for the outer suction cups to hold. This is why the frame with the suction cups must match the size of the transported goods as closely as possible. The bending of the material in particular leads to the suction cup tearing off.

In a single-circuit vacuum system, if one suction cup is overloaded, a leak will occur in the vacuum system and all suction cups will come loose within a very short time. This vacuum loss can no longer be compensated for.

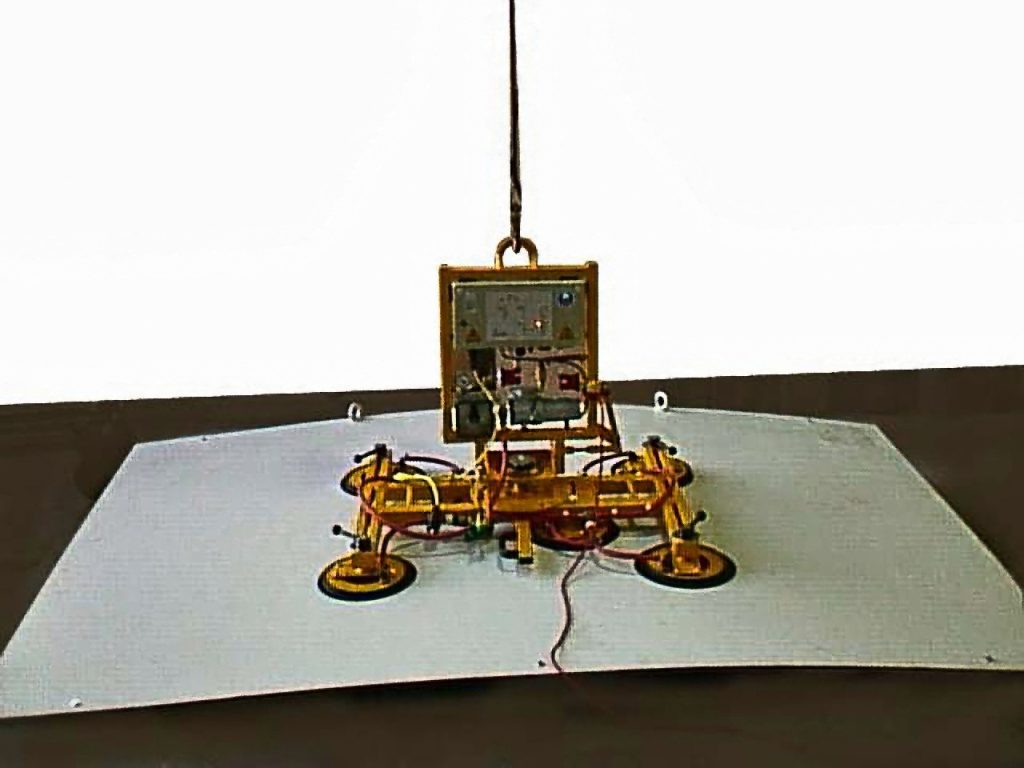

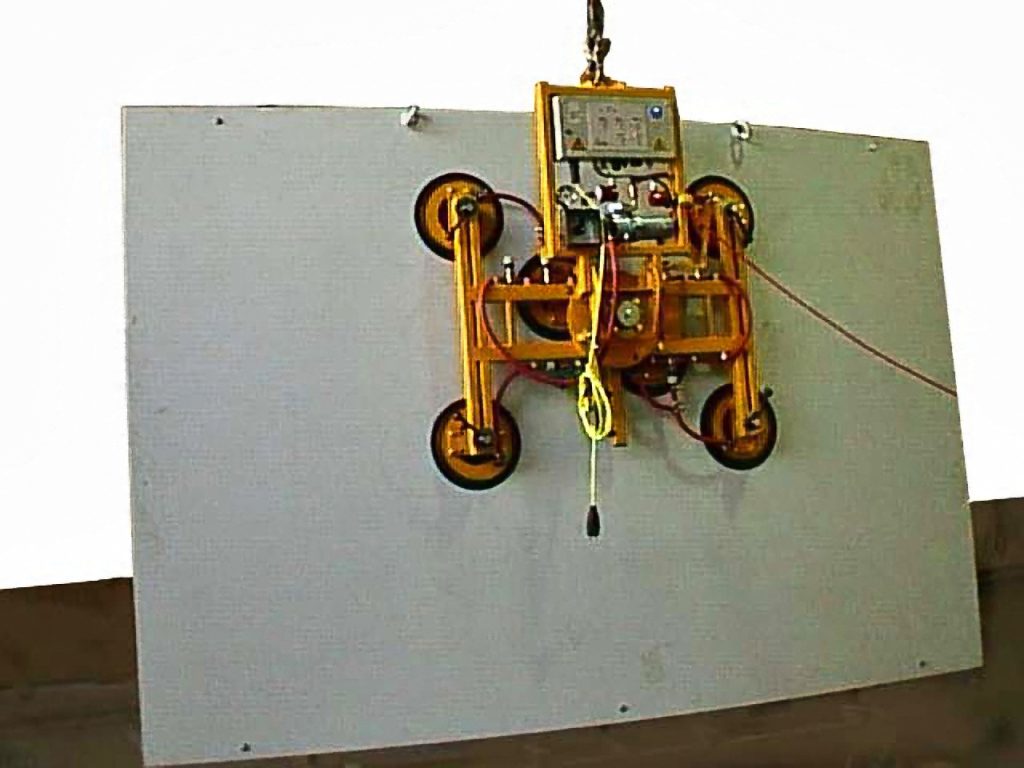

In relation to the Kombi 7011-DS battery-powered device, this means

The 388 suction cups we use can hold approx. 300 kg on a clean glass plate until they are torn off, depending on the type of force applied and the speed, at a vacuum of 0.6 bar without taking a safety factor into account. In theory, a 7011-DS combi with 6 suction cups could hold approx. 1800 kg horizontally (without safety factor).

The frame dimensions are approx. 1.0 x 0.8 m. According to our specifications, materials with maximum dimensions of 2.0 x 1.8 m can be moved.

For example, take a steel plate measuring 3.0 x 2.0 m and weighing approx. 580 kg that you want to move horizontally.

You can then do this for approx. 10 seconds before the steel plate falls to the ground.

(horizontal load case)

If you reinforce the steel plate with beams, transport is possible. Provided you can ensure that there is no deflection.

Stiffness is not quite as important when used vertically, as every sheet material has a certain inherent stability in this direction. Pick up the sheet of paper at one corner with two fingers and hold it vertically so that the 30 cm side is horizontal and the 20 cm side is vertical. The sheet hangs relatively straight, without bending.

If the inherent stability is too low, the bending of the material can lead to the same effect as in horizontal applications.

In relation to the Kombi 7011-DS battery-powered device, this means

The 388 suction cups we use hold approx. 200 kg on a clean glass plate until they slide off, depending on the type of force applied and the speed, at a vacuum of 0.6 bar, without taking a safety factor into account. In theory, a 7011-DS combi with 6 suction cups could hold approx. 1200 kg vertically (without safety factor).

The frame dimensions are approx. 1.0 x 0.8 m. According to our specifications, materials with maximum dimensions of 2.0 x 1.8 m can be moved.

For example, take a steel plate measuring 3.0 x 2.0 m and weighing approx. 580 kg that you want to move vertically.

(vertical load case)

The steel plate is held, but the bending of the steel plate is already clearly recognisable. You are at the limit of what is possible.

However, another factor is of greater importance. This is the lever arm, due to the load not being sucked in at the centre. Greater forces than assumed can act on the suction cup, and an additional load is created by shifting the centre of gravity of the load to the suspension point. This can also lead to the suction cup being overloaded.

Experiment:

To illustrate the force exerted by the lever arm, take a hammer (weighing approx. 250 g). Hold the end of the handle with your thumb and index finger so that the iron part is pointing vertically downwards.

This is the example when the load's centre of gravity coincides with the suspension point, i.e. the load is sucked in centrally.

Now try to hold the hammer handle horizontally so that the iron part is pointing horizontally to one side. Remember, you are only holding the hammer with your thumb and index finger.

Can you now understand the effect of the lever arm on the suction cup? The force you now have to apply is many times greater than before.

If the transported goods are to be rotated vertically, it is extremely important that the transported material is sucked in at the centre of gravity, as otherwise forces with a corresponding lever arm will act that can quickly exceed all calculated safety factors.

The larger the frame, the easier it is to position on the goods. Take a stamp and try to position it in the centre of the sheet of paper (20 x 30 cm) with the naked eye.

Repeat this with a sheet of paper measuring 10 x 15 cm. You will find that it is much easier to centre the 10 x 15 cm sheet on the large sheet (20 x 30 cm) than the stamp.

What is easier for you?

We hope that these explanations have given you a better understanding of the interaction between the size of the carrier frame and the size of the transported goods.